Introduction:

The equipment is controlled by a programmable logic controller (PLC). The main frame is made of stain-less steel, which is welded and manufactured for its aesthetic and durable design, as well as its high precision control components, stable performance, reliable quality, and long service life. Typically, water usage for a cleaning operation is around 10L--15(varying for different products), which is more in line with environmental protection and energy-saving requirements compared to similar products on the market.

Application:

This device is suitable for cleaning rubber,silicone, plastic, iron parts, new magnesium alloy parts,and iron parts with sizes ranging from approximately 1.5mm to 15cm.

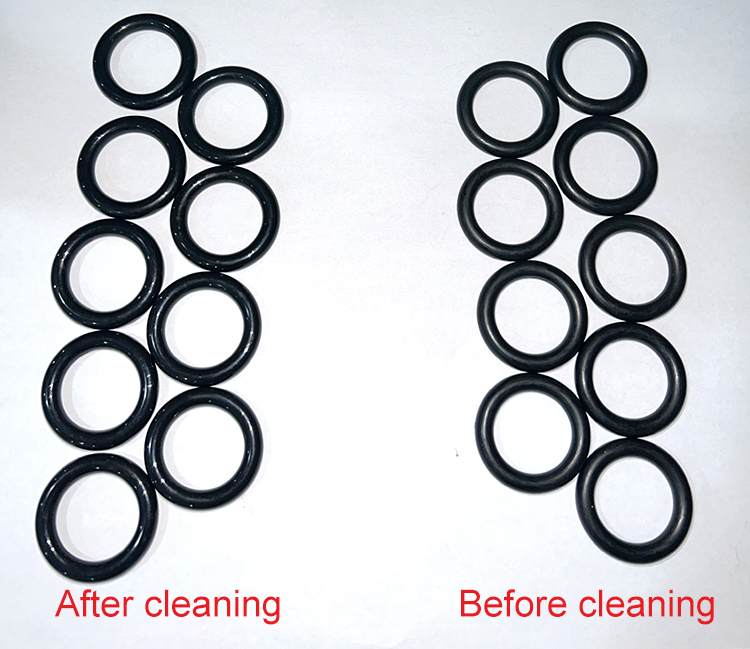

Rubber and silicone cleaning scope:

It can clean off surface debris, dust particles, skin sticking, air-absorbed substances, surface oil and mud of products, as well as reduce static electricity, brighten products, and improve product glossi-ness and hand feel.

Plastic:

It can clean oil stains, water port mold fine wire, static electricity generated by air absorption, etc. lron parts, iron parts, and new magnesium alloy parts:It can clean oil stains, dirt, broken iron fragments, rust stains, and tooling burrs on the surface of the product.

Machine parameter:

|

Liquid storage tank |

Adopt a water tank specifically designed for PC automobiles. Volume: 80L |

|

High-pressure spray |

1. Maximum capacity of the high-pressure cleaning chamber: approximately 100L (effective space) 2. Made of high-quality SUS304 plate with a thickness of 1.2.0mm, it is equipped with water inlet and drainage pipes. 3. Number of spray pipes: 1 set with three nozzles, total water pressure: 1 to 180kg 4. The nozzle is made of stainless steel and the water outlet is in the shape of a 40° fan. 5. High-pressure flushing pump type: The power of the industrial plunger high-pressure pump is 2.2KW |

|

Water circulation filtration (Additional configuration) |

1. Centrifugal water pump 550w brand: Xinjie 2. The filter is made of high-quality 304 plate with a thickness of 1.2mm. Bag filtration, precision filtration 3. Filter 1 ton of water per hour 4. Filter water tank: Dimensions of the sewage tank and pure water tank: 600*500*600 5. Frame structure: Made of 304 stainless steel square tubes |

|

Hot air drying

|

1. Booster fan: 1 unit, power: 3KW, five air outlets 2. Heating component: 1 set, power: 8KW, temperature: 60℃ to 70℃ |

|

Move the door by hand

|

Adopts stainless steel doors and is equipped with acrylic viewing Windows |

|

Cleaning rhythm

|

The cleaning cycle can be adjusted by frequency conversion. |

|

Rotating mechanism

|

The rotating mechanism adopts "RV reducer + motor", with a motor power of 1.5KW and adjustable speed. |

|

Equipment material |

The water contact surface of the equipment is made of SUS304 stainless steel, with a reasonable layout and an attractive appearance. |

Control system:

1.The equipment is controlled by a touch screen, which is convenient for the operator to control.

2.The equipment is controlled by a PLC (Delta) programming controller, featuring automatic operation and manual action.

3.The equipment is equipped with an automatic water compensation device. Automatically compensate for water level.

4. Install an emergency stop button device on the equipment

5.All high-pressure pumps, motors, manual and automatic circulation, and individual interface switches are set on the human-machine interface.

6.Distribution cabinet

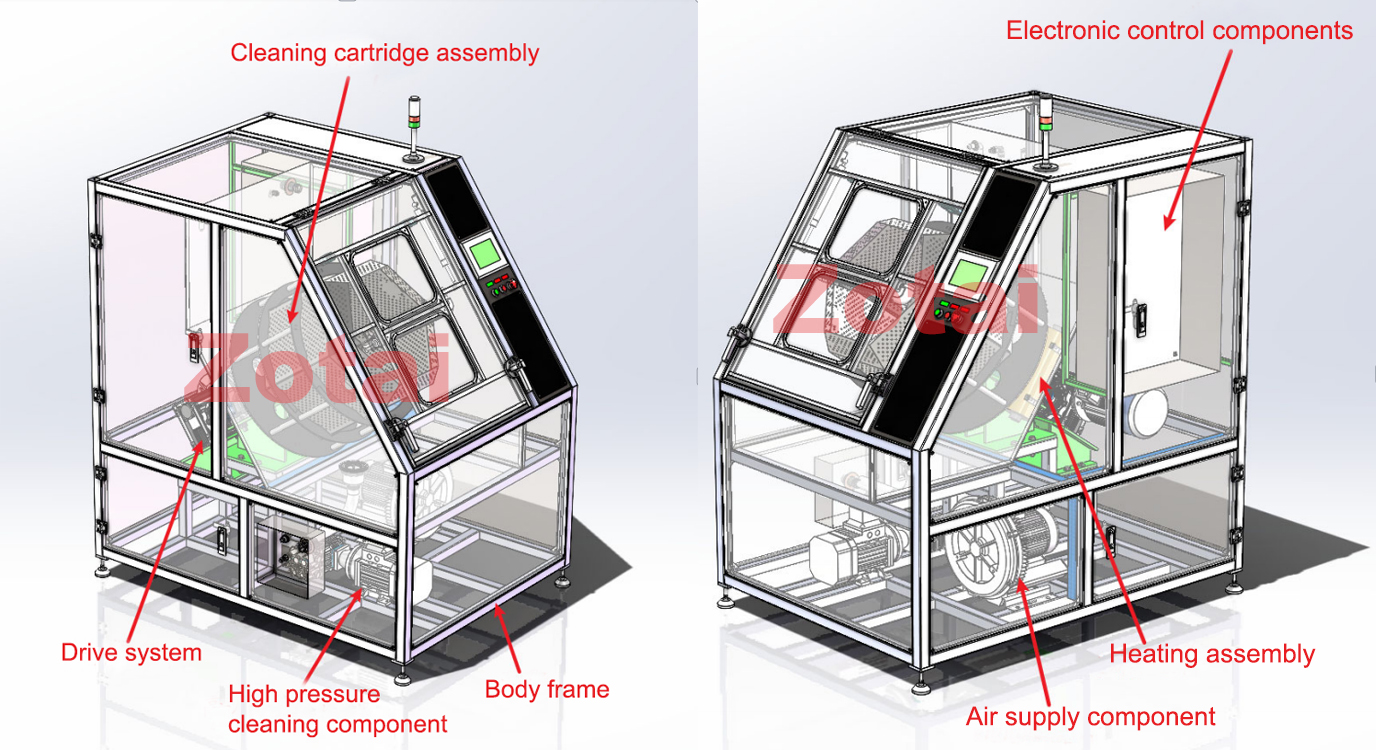

Equipment composition:

1. This equipment is an industrial rubber cleaning machine. Fully enclosed design. The "Delta" PLC control system is adopted, and the cleaning medium uses a special cleaning agent, thus achieving the best cleaning effect for the workpieces.

2. The equipment consists of the following components: cleaning chamber, manual door, industrial high-pressure water pump, frame, pipeline system, rotating system, booster fan, ptc heating component touch screen, etc.